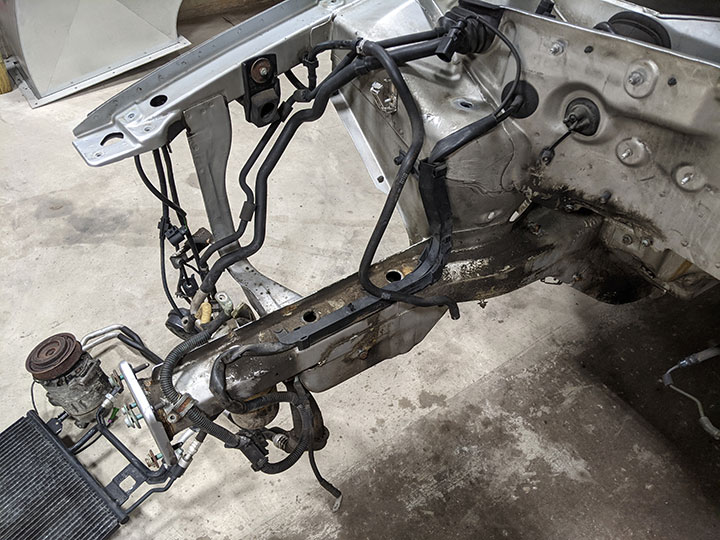

The use of dry ice precision cleaning in conjunction with automotive detailing and restoration is a state-of-the-art process taking over the automotive industry. This process helps bring both older and newer cars back to life by removing years of gunk, debris, dirt, undercoating and contaminants to reveal the parts and intricacies of the car. While there are many cleaning techniques used by professionals, a new method called ‘Dry Ice Auto Detailing’ has created a whole new level of clean. Dry ice automotive restoration provides smart tools that give the operator complete control and the versatility to clean a full spectrum of parts found on today’s automobiles.

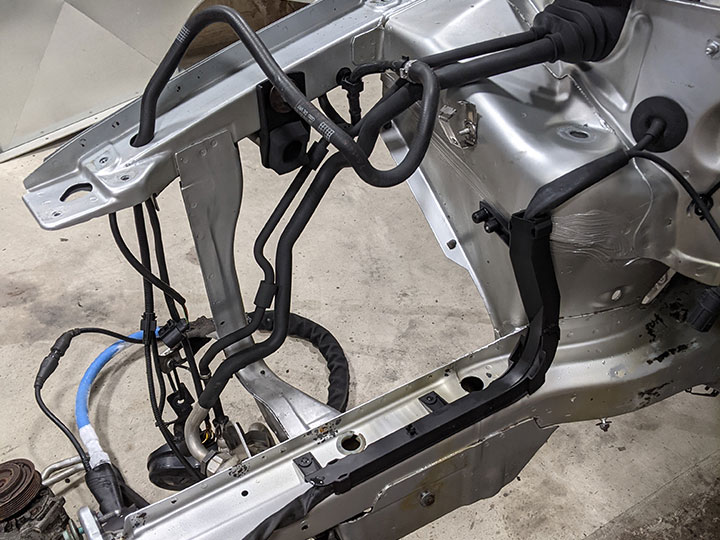

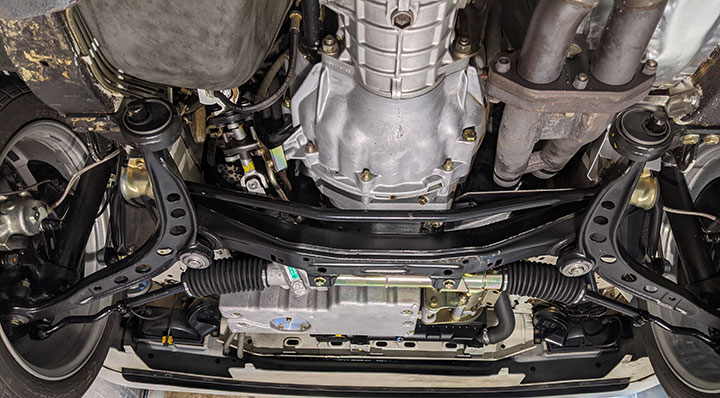

Dry ice blasting is a non-abrasive and non-corrosive cleaning solution that does not produce secondary waste. It also offers a level of versatility that no other process can match using today’s technology. The cleaning aggression can be fine-tuned to effectively clean any part found on the vehicle. This process eliminates the risk of damaging sensitive parts. Dry ice cleaning even provides a solution for tasks which were previously impossible or could only be accomplished while taking up a great deal of time. This method not only removes residues and grease, it can also clean dashboards, plastic parts and the inside of engine bays back to like new condition.

Dry ice is a dry-cleaning media and sublimates to a gas upon impact, which eliminates the need for wastewater collection systems and additional cleanup. Another difference is that dry ice auto detailing will remove all the gunk, oil, and other materials, without removing the vehicle’s paint. This is because, unlike sandblasting or other methods, it’s not the impact of the abrasive materials that remove the dirt. Instead, dry ice upon impact with the surface turns back directly to a gas, which combined with its cold temperature, cleans the surface.

Dry ice blasting is an effective particle spray process for removing stubborn dirt coatings from a range of supporting materials. Dry ice detailing has also proven its worth, especially on complex and delicate surfaces – from upholstery cleaning in cars to cleaning engine compartments and restoration work on classic cars. The main advantage of this technology is that it cleans without leaving any residues, such as waste water, chemicals or spray agent residues.

With all this in mind, dry ice blasting has a number of advantages for car workshops and conditioners: Above all, dry-ice blasting can be used without any issues in all applications where water is off-limits. This is particularly true of delicate vehicle electronics or when working on the bodywork of valuable vintage cars. This prevents potential damage to the delicate electronics caused by cleaning with water, protects parts against corrosive chemicals, protects mechanical tools and removes stubborn encrustations without leaving any residues.